Quality First: Ensuring Excellence in Every Supplement Capsule

The emphasis on supplement quality control cannot be overstated in the intricate world of health and wellness, where dietary supplements have become integral to daily life. Quality control in supplement manufacturing is not merely a regulatory requirement; it is the cornerstone of consumer trust and the bedrock of industry integrity. This blog explores the rigorous processes that ensure each capsule, tablet, and powder meets the highest standards of excellence, underpinning the promise of safety and efficacy.

The Pillars of Supplement Quality Control

1. Sourcing of Ingredients: The Foundation of Purity

The journey of a quality supplement begins with the sourcing of raw materials. High-quality supplements are born from meticulously vetted ingredients for purity, potency, and safety. This involves rigorous testing of raw materials to ensure they are free from contaminants like heavy metals, pesticides, and microbes.

2. Manufacturing Excellence: Precision and Care in Every Step

Once the materials pass supplement quality control checks, they enter the manufacturing phase, where precision is paramount. Facilities adhere to Good Manufacturing Practices (GMP), a set of stringent regulations that govern every aspect of production – from equipment cleanliness to personnel training. These practices ensure that the supplements are consistently produced, meeting the highest standards every time.

3. Testing: Beyond the Basics

Testing is the heartbeat of supplement quality control. Beyond standard tests for ingredient verification, supplements undergo additional assessments for dissolution, bioavailability, and stability. This ensures that not only are the ingredients correct, but they will work effectively in the body and remain potent throughout the product’s shelf life.

4. Traceability and Transparency: The Consumer’s Right to Know

In an era where consumers are well-informed and concerned about what they consume, traceability and transparency are crucial. This involves documenting every step of the supplement’s journey – from sourcing the ingredients to how the product was manufactured and tested. Such transparency fosters consumer trust and underscores a brand’s commitment to quality.

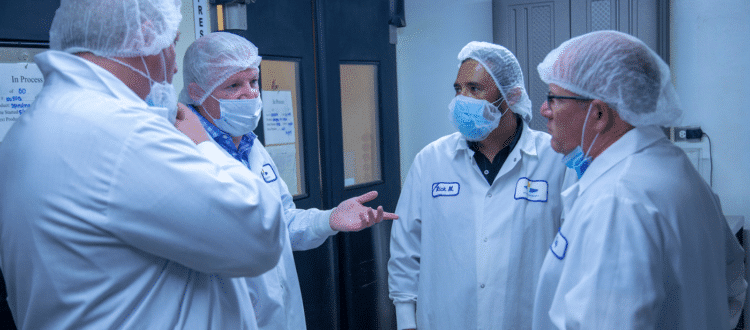

Expertise and Ethics

Behind every supplement quality control process are dedicated professionals who bring expertise and ethical commitment. Scientists, quality control experts, and regulatory specialists work in concert to ensure that every product meets not only the industry standards, but the high expectations of health-conscious consumers.

Third-Party Testing and Certification

Many supplement manufacturers opt for third-party testing and certification to add an extra layer of trust. This involves independent organizations verifying the quality and contents of supplements, providing an unbiased seal of approval. Certifications from organizations like NSF International or USP give consumers reassurance about the product’s quality and safety.

Continuous Improvement and Innovation

Supplement quality control is not a one-time event but an ongoing commitment. It involves continuous monitoring, improvement, and innovation to stay ahead of consumer needs and regulatory changes. This adaptive approach ensures that the supplements maintain their current high standards and are poised to meet future challenges and advancements in health science.

The Promise in Every Bottle

The promise of safety, efficacy, and quality in every supplement capsule is a commitment that the industry takes seriously. It is a promise that safeguards consumer health, builds trust, and upholds the supplement industry’s reputation. As consumers continue to make supplements a part of their daily health regimen, the industry’s dedication to quality first will remain the unwavering standard, ensuring excellence in every capsule, tablet, and powder. Contact Paragon Laboratories to learn more.